This is a higher quality option for your Tikka T3 / T3x striker spring assembly (firing pin assembly). This kit is essential to replace worn components on older or damaged firing pin assemblies, or solving primer ignition issues caused by insufficient spring pressure. It is a useful spare parts kit to have on hand and is difficult to obtain without having to place a special order with Beretta.

Lumley Arms striker spring for Tikka T3 / T3x is longer than the OEM spring and is manufactured from high quality piano wire then zinc plated (silver color) to resist corrosion. Lumley Arms also includes at no extra cost a higher power spring (gold color) made from thicker diameter wire which is approximately 10% stronger (if installed at full length). This higher power spring can be used to remedy primer ignition issues caused by insufficient spring pressure or for those competition shooters looking to chase faster lock times; however, in many cases it will require between 1 to 4 coils cut off to function as desired in your rifle.

When stripping the bolt assembly for cleaning and maintenance after exposure to the elements, most shooters don't consider stripping the firing pin for a comprehensive cleaning. Lumley Arms kit allows you to replace these factory original components upon reassembly.

Advantages of Lumley Arms Tikka Striker Spring Kit:

- Strong and corrosion resistant

- High quality material and construction

![]() Insallation Tech Note:

Insallation Tech Note:

Fitting Guide:

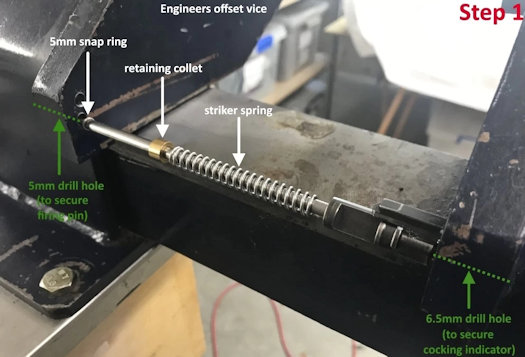

This can be a difficult part to replace and we recommend it’s done by a qualified gunsmith as the removal of the old snap ring and installation of the new one under spring pressure is tricky. The following are the recommended steps to install the components for this kit:

- Wear safety glasses and do not stand in front of the compressed firing pin assembly at anytime.

- The striker pin can be compressed safely in a modified engineers offset vise (or similar). The vise will need a minimum of two small holes drilled in adjacent surfaces. The striker pin hole for assembly needs to be 5mm or 13/64", and the cocking indicator hole needs to be 6.5mm or 17/64" (see image gallery). The alignment of these holes needs to account for the offset of the cocking indicator to the striker pin axis (the cocking indicator orbits the striker pin). Drill the striker pin hole first then position the assembly to mark out the position for drilling the cocking indicator hole.

- If your bench vise is made from thick material, we advise drilling a larger diameter hole just prior to the striker pin hole to accommodate the collet so that when the striker pin is compressed the snap ring is sufficiently exposed so that it can be pried out (see step #4).

- Secure the striker pin assembly by inserting both ends into these holes ensuring a snug fit. Slowly close the vise jaws sufficiently to compress the striker spring so that the snap ring contained underneath the collet is exposed. We also drill a third, slightly larger striker pin hole (5.5mm) for the disassembly step which allows the snap ring to travel through the vise face but locks against the collet. This is optional but makes disassembly easier in our experience.

- The snap ring can be pried open using the tips of two small Stanley screwdrivers or a similar tool and then pulled out using nylon-jawed pliers.

- Dispose of the old snap ring and slowly open the vise jaws, removing the striker pin assembly once the striker spring is fully decompressed.

- Thoroughly clean the striker pin and other components to be retained, remove any burrs (see steps below in 'Maintenance'). Our collets are turned to tighter tolerances than the Tikka factory part you are replacing, at this step we clean the striker pin with 2000 wet and dry after removing any burrs to ensure a tight but functional fit to the collet. The striker pin can be polished beyond this if desired.

- Reassemble using our spring kit by repeating the process above however install the snap ring in front of the collet prior to inserting it back into the vise ensuring the striker pin is in the 5mm sized hole. The new snap ring will expand as it is pushed over the diameter of the striker pin and then close again once it reaches the slot.

- Once the snap ring sits into the slot, use the nylon-jawed pliers to pull back the collet, then compress the snap ring using small needle nose pliers or a similar tool so that it can then fit under the new collet. Opening the vise whilst squeezing the edge of the snap ring will see it slide under the collet. Ensure the new snap ring is completely enclosed by the new collet.

Recommended Tools for Workshop Installation:

- Engineers offset vise (to be modified as below, requires a hand drill and various HSS bits)

- Small nylon-jawed pliers (we use bracelet bending pliers bought from eBay)

- Small needle nose pliers

- 1200 to 2000 grit aluminum oxide paper

- G96 gun treatment or a similar product

- Microfibre cloth

Maintenance:

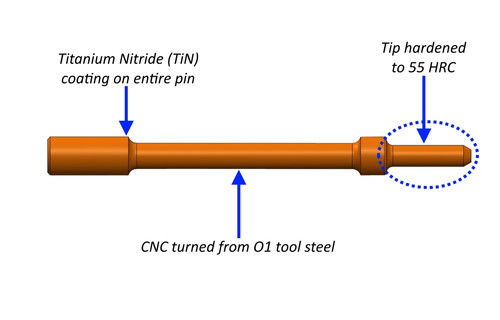

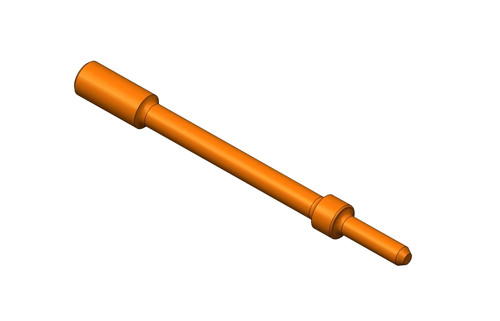

Clean all scale and debris off the striker pin using a suitable gun solvent and then inspect the pin surface to ensure it is burr free. Any burrs can be removed to achieve a smooth/polished surface by starting with 1200 grit wet and dry paper then working up to finer grits from there. Using an ultrasonic cleaner works well for really dirty striker pins. Spray the striker pin with G96 and cleaning thoroughly using a microfibre cloth until it is touch dry, don't apply grease anywhere. Lumley Arms entire kit is made from high quality materials and is resistant to corrosion. Discoloration around the tip of the striker pin is normal and is due to the heat treatment applied during manufacturing.

| Product Features: |

- 1 x 'standard' striker spring (27.2 coils, 1.4mm wire - Silver color)

- 1 x 'higher power' striker spring (30.0 coils, 1.5mm wire - Gold color)

- 1 x retaining collet

- 3 x 5mm snap rings

- Material:

- The striker springs are made from a high-quality spring steel then zinc plated

- The snap rings are made from stainless steel spring wire

- The retaining collet is CNC machined from pre-hardened 17-4 grade stainless steel then TiN coated to the gold color (the original Tikka part is made from an aluminum alloy)

- Made in Australia by Lumley Arms INC.