The CoreLock™ adjustable ratchet lever can be used to replace the threaded thumbnut on Harris S-series Bipod setups. The metal insert components are made of stainless steel for excellent resistance to corrosion and for use where stainless steel is a requirement. Unlike some of our competitor products, CoreLock™ System uses Zinc Die-Cast handle and Black Oxide Coated Steel Spacers for added durability and strength.

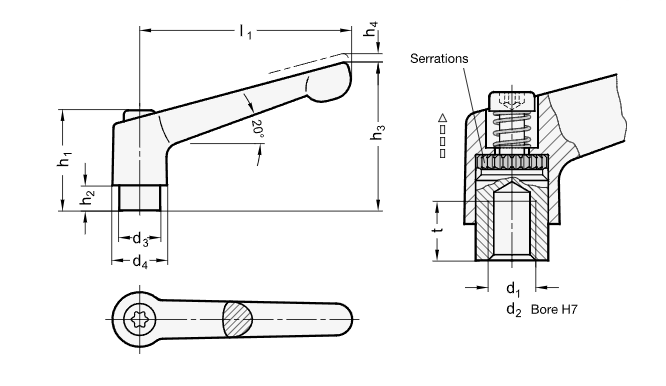

The CoreLock™ adjustable hand levers are the result of modern industrial design. All such levers have proven to be ideal wherever parts have to be clamped in a confined space or in a particular lever position. Pulling the lever upwards, disengages the internal mechanism, allowing it to be swivelled to the ideal clamping position. When releasing the lever, the internal mechanism automatically re-engage.

|

l1

|

d3

|

d4

|

h1

|

h2

|

h3

|

h4

|

t

min |

A/F

|

|

1.77

(45.0) |

.39

(10.0) |

.51

(13.0) |

.96

(24.5) |

.16

(4.0) |

1.38

(35.0) |

.14

(3.5) |

.35

(9.0) |

.12

(3.1) |

Advantages of Angled CoreLock™ System:

- No tools needed to adjust: Harris Bipod can be locked and unlocked with your figures while in position within seconds.

- Spring loaded lever: Replaces the Harris lock nut and provides plenty of leverage to lock or unlock the swivel using only your fingers.

- No permanent alteration: Your bipod can be restored to issue configuration within a few minutes.

- Low profile: The locking lever can be pulled back slightly to disengage the internal ratchet without effecting the lock tension. Thus, the CoreLock™ clamp lever can be “parked” against the stock to minimize snags when you are on the move.

| Product Features: |

- Compatibility: Fits all Harris S-series (Swivel) Bipod Series

- Handle: Angled Zinc die-cast

- Insert & screw: Stainless steel

- Spring: Stainless steel

- Spacer: Black Oxide Coated Steel

- Installation Documentation: Included

- RoHS Compliant

- Made in Germany